Related .PDF files

62,736 plastic display boxes were damaged upon arrival in Ft. Worth, Texas. Two container shipments of acrylic display boxes were fabricated in China and shipped to Long Beach, CA where they were transported via rail to Ft. Worth. One order arrived undamaged but 85% of the boxes in the second order were broken.

Rapperport Associates was engaged to determine why one shipment of boxes arrived completely intact while the contents of the other shipment were so badly damaged. It was initially suspected that the damage was the result of mishandling during shipping but the display boxes were well packed and no damage was observed in the packaging materials or with the shipping container.

We traced the failures to the difference in elevation change between the rail routes between the two shipments. The shipment that arrived intact experienced a maximum altitude of 4,612 ft during rail transit and the shipment that was badly damaged was subject to a maximum elevation of 7,355 ft during rail transit. The boxes were hermetically sealed which prevented the interior box pressure from equilibrating with the decrease in atmospheric pressure from elevation gain during transit. The higher elevation resulted in a greater pressure differential from inside to outside the box (3.48 psi versus 2.26 psi) which caused the boxes to burst.

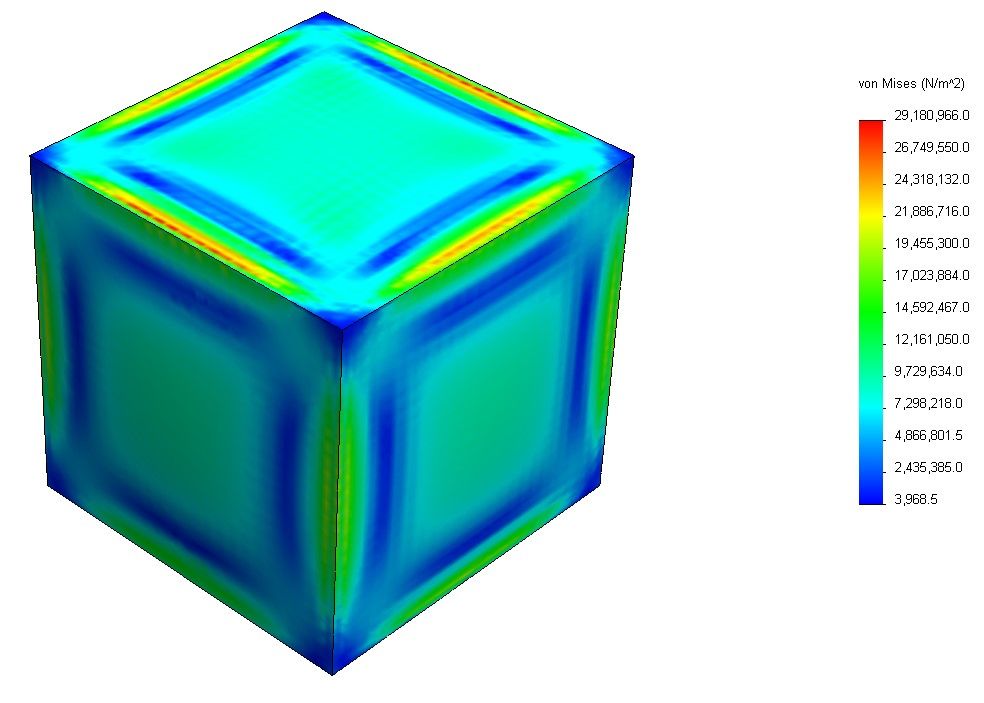

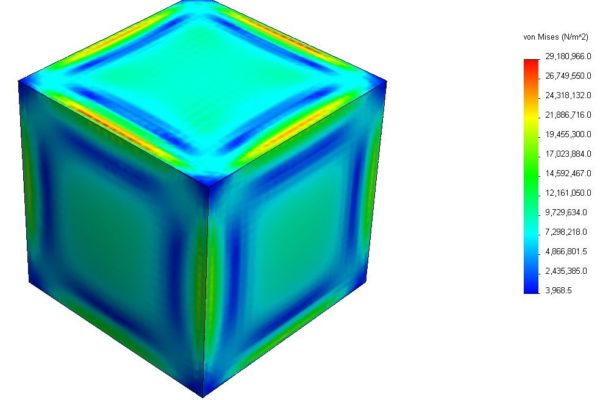

This failure mechanism was confirmed by a finite element stress analysis which predicted box failure at the higher elevation but not at the lower elevation and was also remarkably consistent with exemplar pressure testing.